eVald

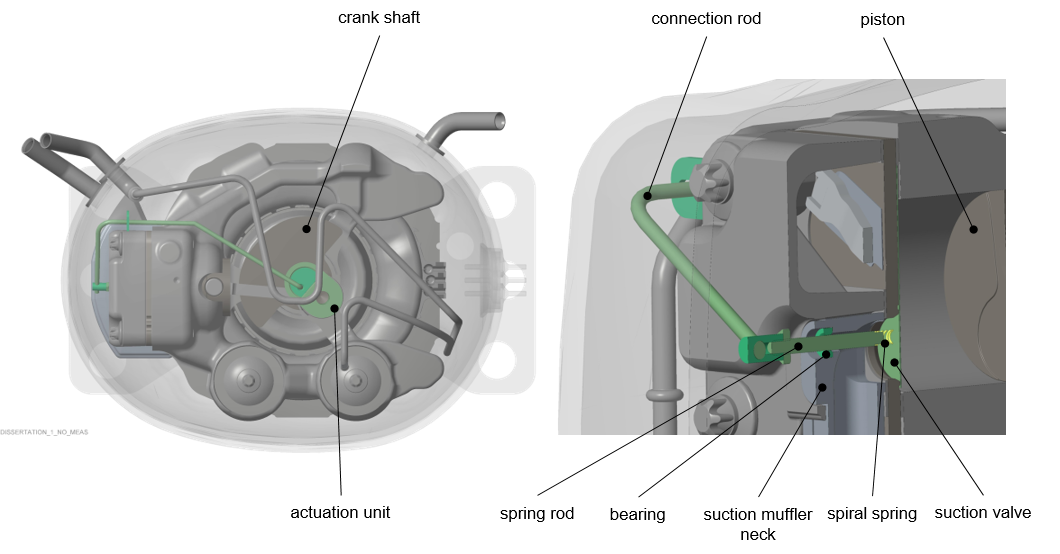

Mechanically assisted suction reed valve

The refrigeration sector holds approximately 20 % of the global electrical energy consumption and is expected to grow further. An analysis of the electrical energy consumption in a common European household indicates that refrigeration appliances are among the largest electricity consumers. While up to now, mainly fixed-speed compressors are used to drive the refrigeration cycle of domestic refrigeration appliances, it has already become clear that future energy efficiency saving requirements in domestic refrigeration can only be achieved by means of variable-speed compressors. Variable-speed compressors are equipped with the same valve concept as fixed-speed compressors which often leads to insufficient valve dynamics. The valve dynamics of reed valves, which are widely used in compressors for domestic refrigeration, is crucial in terms of efficiency, cooling capacity, reliability and acoustics of the compressor. Especially in variable-speed compressors, a further improvement of the valve dynamics requires the consideration of a new valve concept.

In this work, a new and cost-effective concept of a mechanically assisted suction reed valve (MASV) is introduced. An in-house compressor simulation model was adopted to include the new MASV concept. After validation with measurement data, simulation-based surrogate models were created to systematically optimize the design in terms of energy efficiency (COP), cooling capacity, reliability and acoustics using a multi-response optimization approach. In addition, extensive measurements were carried out to experimentally investigate the MASV regarding its actual improvements at various operating conditions.

COP improvements up to 3.6 % and cooling capacity improvements up to 6 % were measured with one of the optimized design variants, whereby higher compressor speeds tend to achieve better results than lower speeds. It turned out, that valve closing delays and the associated gas backflow is particularly critical at high compressor speeds. Simulation results at 5000 rpm showed that the optimal design variant is capable of increasing the suction mass up to 22 % by reducing the valve closing delay. In addition, fewer intermediate valve impacts and a substantial reduction in valve impact velocity reduce valve stress and thus increase the reliability of the compressor.

Not only technically, but also from an economic point of view, the MASV seems feasible given the simplicity of the concept and the benefits that can be achieved with it. The application of the MASV in all future compressors used in domestic refrigeration could lead to annual electricity savings of approximately 2.7 TWh - 5.5 TWh, which is equivalent to approximately 3.8 % - 7.6 % of Austria's annual electricity consumption in 2019.

The research project was funded by the Austrian Research Promotion Agency FFG (funding program: "Bridge 1 – 25th call"). It started in July 2017 and lasted a total of 2 years and 9 months. The research project was carried out in cooperation with Secop GmbH.

Figure: Hermetic reciprocating compressor equipped with a mechanically assisted suction reed valve.